Advanced Ceramic Processing Water

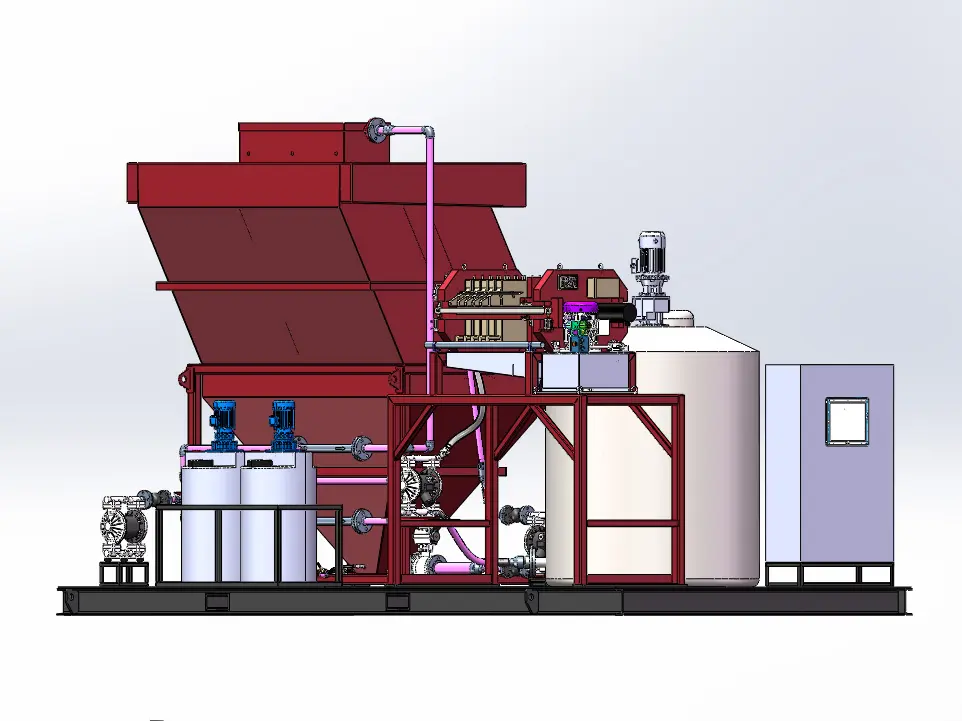

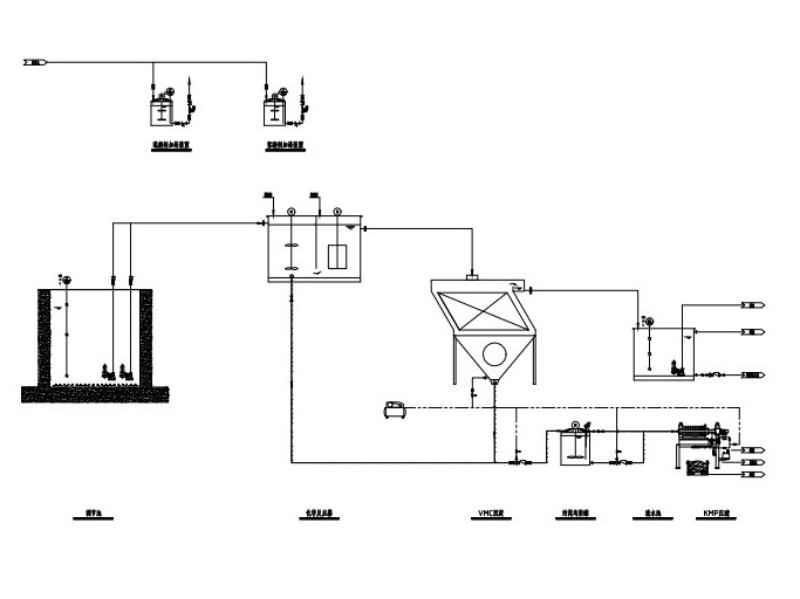

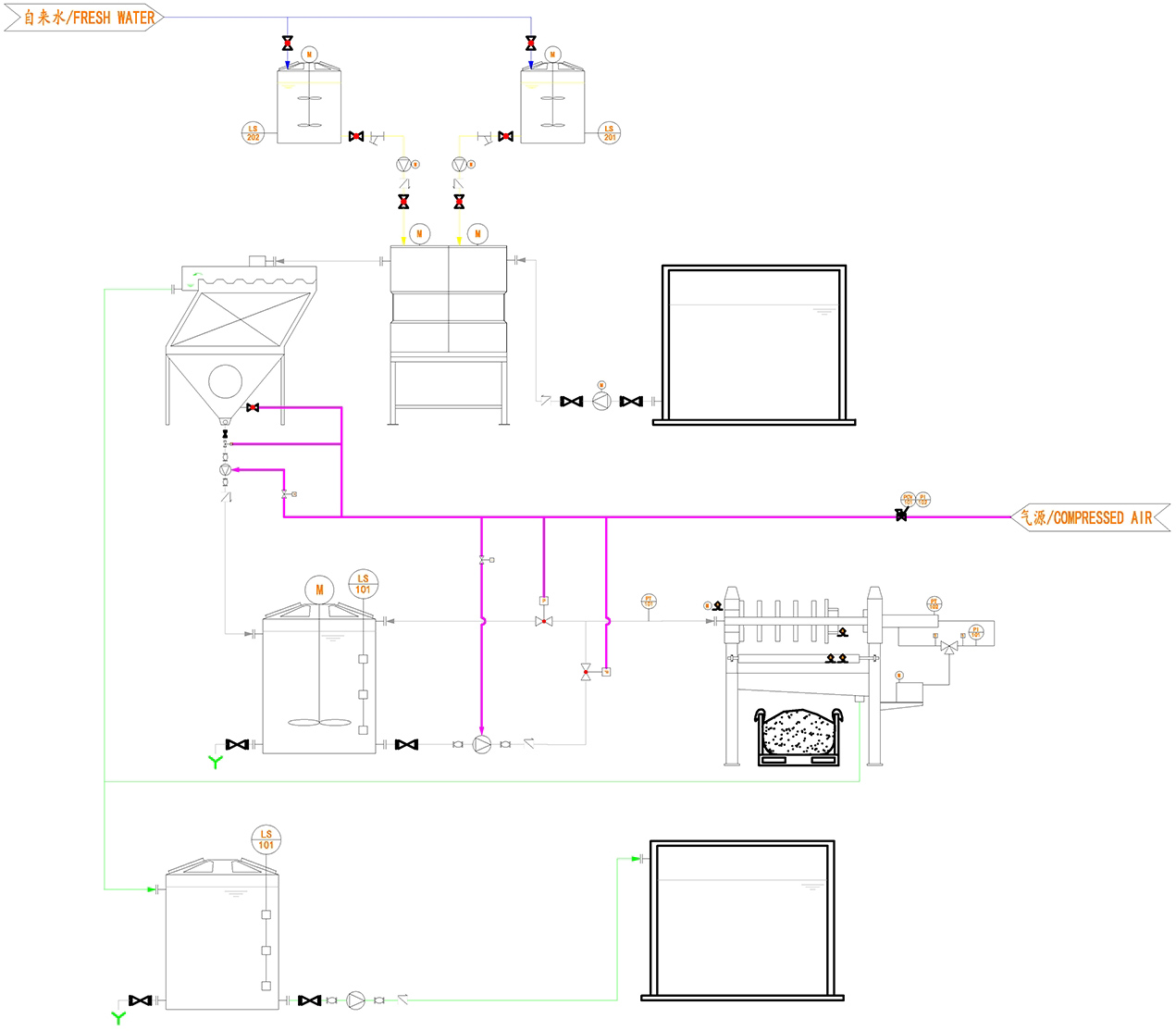

Process flow chart

Wastewater Quality

Industry |

Special ceramics |

|||

Parameter |

Unit |

Inlet |

Outlet |

Remark |

Flow |

m³/h(d) |

40 |

/ |

|

pH |

/ |

7~8 |

7~8 |

|

Suspended solids |

mg/l |

2000 |

200 |

|

|

Heavy metal Cr/Cu/Ni/Zn/Fe... |

mg/l |

/ |

/ |

|

Other |

|

/ |

/ |

|

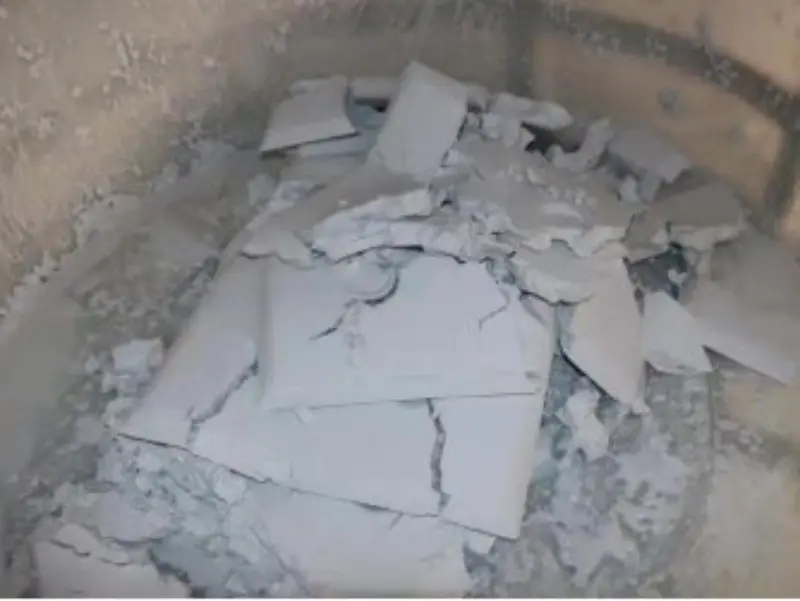

Moisture content of mud cake |

% |

≤30 |

||

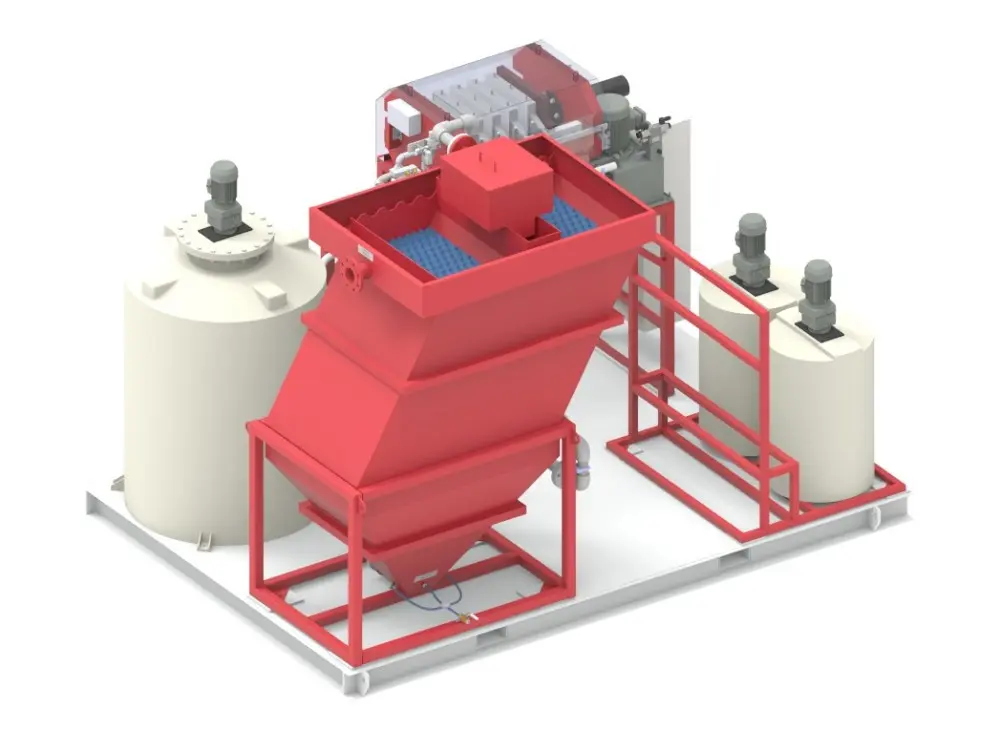

Configuration Table

Sewage treatment capacity 5-75m³/h

name |

Basic Configuration |

quantity |

Upgrade Configuration |

quantity |

Complete Configuration |

quantity |

System Description |

Reaction system |

Mud pump |

1 unit |

Mud pump |

1 unit |

Mud pump |

2 units |

The reaction system mainly adds chemical agents such as coagulants and coagulants to the sludge to promote flocculation of sludge particles and improve its dewatering performance. |

Pipeline mixer |

2 |

MR reaction pool |

1 set |

MR reaction pool |

1 set |

||

PAM dosing tank |

1 |

PAM dosing tank |

2 |

PAM integrated dosing device |

1 set |

||

PAM dosing pump |

1 unit |

PAM dosing pump |

1 unit |

PAM dosing pump |

2 units |

||

PAC dosing tank |

1 |

PAC dosing tank |

2 |

PAC dosing tank |

2 |

||

PAC dosing pump |

1 unit |

PAC dosing pump |

1 unit |

PAC dosing pump |

2 units |

||

Electromagnetic flowmeter |

/ |

Electromagnetic flowmeter |

/ |

Electromagnetic flowmeter |

1 |

||

Sedimentation system |

VMC Sedimentation Tank |

1 unit |

VMC Sedimentation Tank |

1 unit |

VMC Sedimentation Tank |

1 unit |

The sedimentation system is mainly used to concentrate sewage and facilitate filter pressing. |

Pneumatic mud valve |

1 |

Pneumatic mud valve |

1 |

Pneumatic mud valve |

1 |

||

Mud pump |

1 unit |

Mud pump |

1 unit |

Mud pump |

2 units |

||

Recycled water reuse system |

Grey water collection barrel |

1 |

Grey water collection barrel |

1 |

Grey water collection barrel |

1 |

The grey water collection system is mainly used to reuse the concentrated supernatant to reduce costs and save expenses. |

Drain pump |

1 unit |

Drain pump |

1 unit |

Drain pump |

2 units |

||

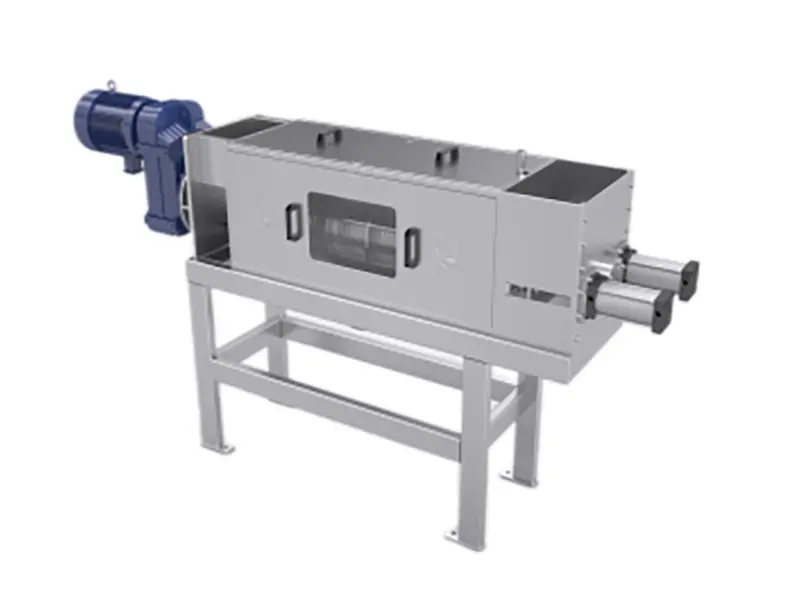

Filter press system |

Homogenizing mixing tank |

1 |

Homogenizing mixing tank |

1 |

Homogenizing mixing tank |

1 |

The main function of the filter press system is solid-liquid separation |

Feed pump |

1 unit |

Feed pump |

1 unit |

Feed pump |

2 units |

||

KMP filter press |

1 set |

KMP filter press |

1 set |

KMP filter press |

1 set |

||

Control System |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

PLC control cabinet |

1 set |

All the automation controls of our equipment will be integrated into this system and run fully automatically |

Supplementary materials |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

Pipes, valves, cables, etc. |

1 batch |

The specific quantity of cables, pipes and valves required within the system depends on the customer's on-site conditions. |

Please ask our sales consultant for a detailed system configuration list.

Feature Comparison

Function |

Basic Configuration |

Upgrade Configuration |

Complete Configuration |

Fully automated control |

√ |

√ |

√ |

Fault alarm |

√ |

√ |

√ |

Automatic reaction vessel |

- |

√ |

√ |

Automatic standby switching |

- |

- |

√ |

Automatic adjustment of dosing |

- |

- |

√ |

Whether frequency conversion control |

- |

- |

√ |

Soaking interval time |

4 hours |

8 hours |

Fully automatic |

Optional functions

Serial number |

name |

illustrate |

effect |

1 |

Special anti-corrosion |

Internal liquid contact parts are three-cloth and five-oil glass fiber anti-corrosion |

Prevent corrosion from high acid, high salt, high fluorine, etc. |

2 |

Special materials |

304/316L etc. |

Select according to user material characteristics |

3 |

Overall skid mounted |

Patterned steel platform + fixed bracket + cable duct, pipeline, cable, etc. |

Easy to install, transport and move flexibly |

4 |

PH automatic adjustment |

PH online monitoring + integrated control + acid and alkali dosing system |

Make the effluent reach the standard PH value |

5 |

Fine filter |

Contains multi-stage centrifugal pump |

Reduce the content of suspended solids in the filtrate and adjust the water quality |

6 |

Explosion-proof |

DⅡBT4/CT4 etc. |

Electrical components, motors, etc. placed in explosion-proof areas are divided into different levels |

7 |

Conveying system/temporary storage system |

Conveyor/sludge hopper |

Mud cake can be collected through conveying equipment or temporary storage system, reducing labor |